CEDAR STRIP CANOE BUILD: PLANS, PREP, AND PROGRESS

One of my goals for 2018 is to build a cedar strip canoe. I wanted to document the process here in case anyone is looking for information for their own canoe building projects.

Also, I have no idea what I’m doing so it should be entertaining if nothing else.

This post may include affiliate links. As an Amazon Associate I earn from qualifying purchases. Find more info in my privacy policy.

This post is basically an overview of the project that talks about the what, where, and how I’m planning on constructing this thing.

CHOOSING A PLAN

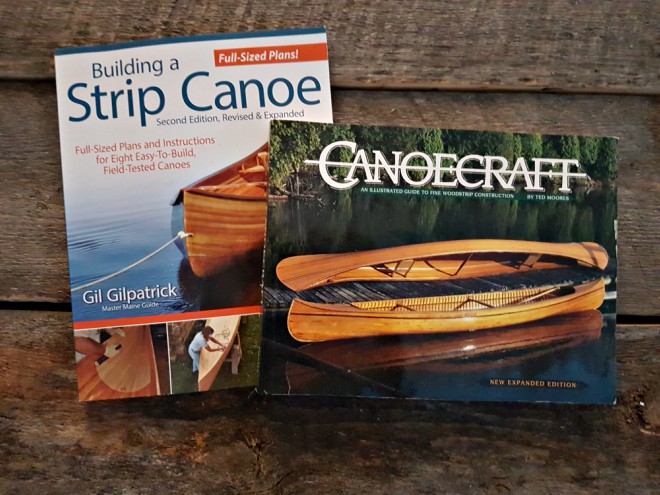

The first thing I did after deciding to tackle this project was buy a few books written by people who actually know things about canoe building. Canoecraft by Ted Moores and Building a Strip Canoe by Gil Gilpatrick seemed to be the go-to books among the canoe-building community. I also picked up Canoe Paddles by Graham Warren and David Gidmark.

Reading through the books for the first time was a little bit overwhelming and a whole lot confusing. The number of steps involved is daunting and it didn’t help that I wasn’t familiar with most of the terminology. Choosing a plan to follow meant deciding on things like: if I wanted the gunwale beam tumblehome, if I wanted a plumb bow or a high recurve, and if I should include a keel and stems. (If any of those words make sense to you, you’re leaps and bounds ahead of where I was at when I started this)

After reading the books, studying the diagrams, and watching a few YouTube videos, I got a better feel for what type of canoe we would build based on what we were looking to use it for. We wanted something that’s suitable for wilderness trips and big enough that Juno can fit in it (not that she’s ever going to willingly get into a tippy canoe, but we can dream).

We settled on the 18’ E.M. White Guide model out of Gilpatrick’s book. It seems like a general work horse type boat that is plenty big enough to fit gear and supplies for longer trips. We’ve altered the plan ever so slightly to include stems (strips of hardwood running along both ends of the canoe), but otherwise have stuck to the plans included in Building a Strip Canoe.

The strongback

CHOOSING A PLACE TO BUILD

Everything I read about canoe building emphasized the importance of finding a good spot for building the boat before you actually get started. You need to consider things like space, ventilation, and ability to control the climate. You also have to put it somewhere that you’re not going to mind having a semi-constructed canoe sitting for months on end and somewhere you can actually get the boat out once it’s finished.

We decided that our basement was the best option. We don’t use it for much, it’s in bad need of renovation anyway, and it’s easily accessible. If we’re reading the plans right (which we’re probably not) and if our measurements are correct (which they probably aren’t) then we should be able to get the fully constructed canoe out of the basement via the window. I read one account of a couple who had to basically deconstruct half their house to get their finished boat out of their basement, so here’s hoping that we made the right choice on this.

The forms

PROGRESS SO FAR (OR LACK THEREOF)

I haven’t exactly come out of the gate strong on this project. It’s coming up to the end of March and I haven’t checked much off the to-do list. Mark helped me build the strongback (the big, long table that the forms go onto), and I traced, cut, and sanded the forms (they make up the skeleton that the cedar strips are then molded around). And that’s about it. Most of the prep work is fairly tedious and you want to be meticulous about it. If something is off on the forms or the strongback, it can affect the entire building process.

Next steps include:

- Attaching the forms to the strongback

- Ordering supplies (like epoxy, fibreglass cloth, etc.)

- Purchasing the cedar lumber

- Ripping strips of cedar and maple (which I’m using for the stems)

- Forming and gluing the stems

- Routing a bead and cove edge on the cedar strips

And that’s all before we even start the actual boat building process. I’d better get going if I want to complete this canoe while I’m still young enough to paddle it.

Keep an eye out for more step-by-step posts on this project and updates on how it’s going.

Where can I get the PDF templates to print in full size?

Hi Luis, if you mean you’re looking for the form templates in a PDF, I’m not sure that they are available in that format. I purchased the book by Gilpatrick which included the templates. Hope that helps!

How many sheets of plywood did it take to build the forms? Thanks

I used 2 – 4’x8′ 1/2″ sheets for the forms.